We make Folding and Gluing Easy!

Do you have a product that requires packaging? Would you like a folder for your sales material that reflects your brand? Or do you have a unique idea for showcasing your company’s message? At Southport Printing Co. we can fold and glue printed materials to almost any shape and size to bring your idea to life!

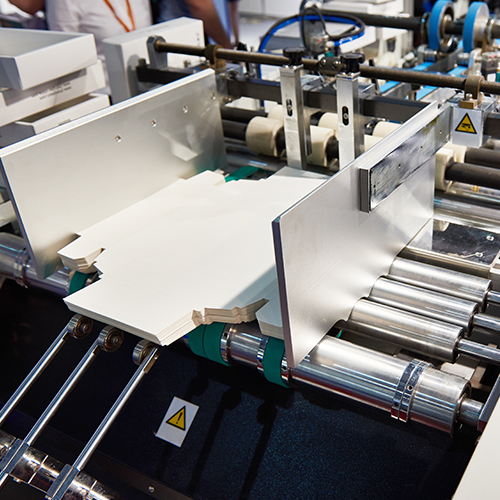

Three-dimensional items that require folding and gluing start with a flat piece of material.

The material is printed, then scores are made along the fold lines into the flat material. From here, the material is folded and glued if necessary to create a 3-dimensional finish.

At Southport Printing Co. our inhouse team hand finish folded and glued print jobs on a daily basis. These jobs can be simple, such as a single fold, right through to complicated boxes or sleeves for documents, or anything that customers can dream up that they would like us to create!

We love helping customers with jobs that are ‘outside the box’.

Our skilled team of Graphic Artists and Sales Managers help take ideas through to reality while offering advise along the way to ensure that the job is designed and printed in a cost-effective manner. There are several key factors to getting this right which our team help customers work though:

Selection of the Correct Materials for the Job

Don’t limit your creation to standard paper stock. There are many options including textured stocks, cardboards and even plastics that can be used to create the perfect item.

Precision Design of Artwork – No Room for Error!

Imagine spending all that time and money designing the perfect box, then when it comes off the printer it is not square or the printing is not on the right section of the box! Complex jobs that require folding and gluing must have accurate artwork for the perfect finish. Our specialised graphic designers have the skills and know-how to get the job right the first time.

Embossing or Debossing

Embossing and debossing are 3-dimentional effects achieved by a metal plate being applied with pressure to create a 3-dimensional impression on the focus area.

This is an effective way to add a tactile dimension to your print job. Often a small feature is all that is required to make your job standout. We will guide you with advice on the best place to add a feature such as this, in a cost-effective way.

Additional uses for Gluing

Gluing extra pieces of materials to an original piece can create a great point of difference.

Tipping

Tipping is frequently used to attach an item to a printed product. Examples of this include gluing a sample product or coupon code to a print job. The word tipping simply means adding an item to a printed product that is intended to be removed by the customer for use.

Windowing

Windowing is a creative way to grab customers’ attention, but is also used to protect the print job. The term windowing refers to a film of plastic being glued over all or some of the print product. In a recent job that was produced at Southport Printing Co., windowing was used to showcase chocolate balls inside a custom designed box.